Over 20 year’s of experience

About Duran’s Boat Repair

Since 1998, Salvador Duran has been the anchor of quality boat repair in the Galveston Bay/Clear Lake Area. With over four decades of expertise stemming from his humble beginnings in 1982, Salvador’s dedication to high-quality work is renowned throughout the region.

At Duran’s Boat Repair, every vessel tells a unique story. Our passion for boats is as deep as the waters we call home. From routine maintenance to intricate repairs, we blend experience and commitment to keep your adventures afloat.

Contact Duran’s Boat Repair for exceptional service, reliability, and high quality boat repair.

Our Services

Opening in the boat repair business in 1998. Learned how to work on boats in 1982, high quality work is renowned in the area.

Works and resides in the Galveston Bay/Clear Lake Area. Over forty years of boat repair experience.

Topside Paint – Topside & Hull Painting

Bottom Jobs

Fiberglass Repair

Prop Speed

Topside Paint – Topside & Hull Painting

Our seasoned team of marine painters and specialists, adept in transforming vessels with over two decades of expertise. Our facility offers top-tier resurfacing and premium coatings for yacht exteriors above and below the waterline. Committed to excellence, we only use top professional marine products, understanding the significance of safeguarding your investment. A fresh coat not only shields your boat but elevates its aesthetic appeal and eases maintenance, ensuring your satisfaction. Choosing the right paint involves more than cost; understanding brand-specific formulas, primers, and surface preparation methods is crucial. While a DIY approach yields professional results at a fraction of the cost, meticulous surface preparation remains paramount for a flawless finish, echoing our meticulous standards.

Bottom Jobs

Our expertise includes vital bottom jobs for boats of all makes and models. Our powerboat repair center, equipped with a lift, ensures thorough servicing for increased hull longevity, Repainting the boat’s bottom safeguards against deterioration, boosts water navigation, and enhances fuel efficiency. Beyond impeccable bottom job expertise, Duran’s professionals offer value by addressing dings, dents, scuffs. Trust Duran’s Boat Repair for an expert approach to boat maintenance, saving you both time and money while extending the life of your cherished watercraft.

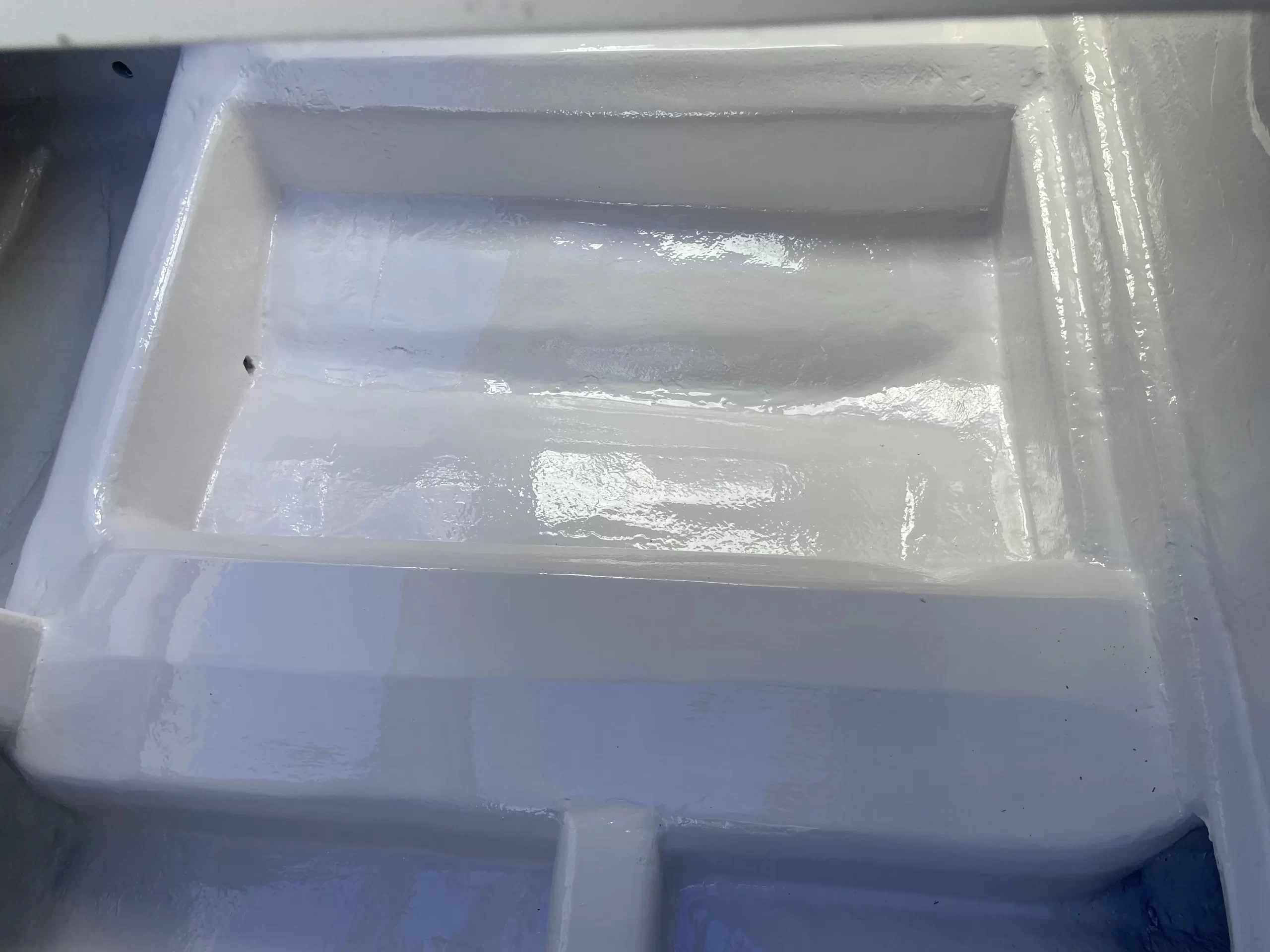

Fiberglass Repair

We specialize in restoring fiberglass boats marred by accidents, storms, or collisions. Boasting over two decades of experience, our expert team delivers superior fiberglass repairs for boats of any make, model, or manufacturing year. Demonstrating top-notch skill, we offer convenient and affordable services to address a spectrum of damages. From cosmetic dings to structural issues, Duran’s Boat Repair’s fabrication team excels in crafting custom fiberglass components. We also to comprehensive fiberglass repairs, including addressing cracks, structural damage, and stress cracks. The mastery of Duran’s Boat Repair’s fiberglass craftsmen shines in our commitment to making each boat look brand new, covering everything from engine vents to transom doors. Our extensive experience, coupled with advanced facilities and equipment, ensures a flawless restoration of any fiberglass boat component.

Prop Speed

Prop speed is a foul release coating system that is used on propellers and other metal parts below the waterline of boats to prevent marine growth.

Underwater Services for Running Gear

Fiberglass For Sonar

Our fiberglass for sonar offerings include various mounting options tailored for different vessels. Transom mount transducers, placed at the stern, ensure easy installation without drilling beneath the waterline. These offer adaptability, adjustable angles, and foldable features for safe trailering, ideal for smaller boats with planning hulls.

Fiberglass for Seakeeper Installation

The Seakeeper installation offers a transformative experience for boaters, minimizing up to 70% of the boats pitch and roll during navigation, ensuring a smoother ride and reducing the likelihood of seasickness among passengers. Duran’s Boat Repair skillfully integrates this system, creating a structural fiberglass platform for its secure placement in the bilge.

Frequently Asked Questions

How often does a boat need a bottom job?

The frequency of needing a bottom job for a boat typically ranges from every 1 to 3 years, contingent upon various factors. Factors include the type of water (salt or freshwater) the boat frequents, the hull material, the type and quality of antifouling paint applied, and the environmental conditions. Boats in saltwater or warm climates often require more frequent maintenance due to increased marine growth and harsher conditions. Conversely, boats in freshwater or colder regions might have longer intervals between bottom jobs. Regular inspections and considerations of these factors help determine the optimal timing for a bottom job to ensure the hull remains clean, efficient, and protected against marine growth and corrosion.

What ruins a fiberglass boat?

A fiberglass boat can deteriorate due to various factors. Impact damage from collisions or hitting submerged objects can cause structural cracks or punctures in the hull. Water intrusion, if the fiberglass laminate is compromised, leads to delamination, blistering, or weakening of the structure. Continuous exposure to UV rays fades the gelcoat and weakens the fiberglass material. Osmosis, forming blisters due to water penetration, compromises structural integrity if left unchecked. Neglecting maintenance—such as skipping cleaning, waxing, or repairing scratches—accelerates deterioration. Stress from rough waters or improper storage can cause structural damage or cracks. Additionally, using harsh chemicals damages the gelcoat or fiberglass material, leading to discoloration or weakening. Regular maintenance and prompt repairs are crucial to prolonging a fiberglass boat’s lifespan and preventing significant damage.

How do you fix deep gouges in a fiberglass boat?

Repairing deep gouges in a fiberglass boat involves several steps. First, clean the damaged area thoroughly to remove any debris or contaminants. Then, using a grinder or sandpaper, carefully feather the edges of the gouge to create a gradual slope around the damaged area. Next, apply multiple layers of fiberglass cloth or mat and resin, ensuring each layer is fully saturated and smoothed out to match the hull’s contour. Allow the resin to cure completely between each layer. Once the layers have hardened, sand the repaired area to achieve a smooth finish. Finally, apply gelcoat or a finishing compound to match the boat’s original surface, followed by buffing and polishing to blend the repair seamlessly with the surrounding hull.

How often should you change a cutlass bearing?

Cutlass bearings in a boat typically require replacement every 5 to 7 years or after around 1,000 to 2,000 engine hours, although this can vary based on usage and environmental conditions. These bearings support the propeller shaft, and wear and tear from friction and water can cause degradation over time. Signs of a worn cutlass bearing include increased vibration, excessive shaft play, or unusual noises from the stern tube. Regular inspections during haul-outs or maintenance checks are essential to assess the bearing’s condition. Timely replacement prevents potential damage to the shaft or the surrounding components and ensures optimal performance and safety while navigating.

How long does topside boat paint last?

The longevity of the topside boat paint depends on various factors such as the quality of the paint used, the application technique, environmental conditions, and maintenance. High-quality marine paints, when properly applied and maintained, can last anywhere from 7 to 10 years before needing a new coat. However, boats exposed to harsher conditions, frequent use, or intense UV exposure might require repainting sooner, perhaps every 2 to 4 years. Regular cleaning, waxing, and avoiding abrasive cleaning agents can extend the lifespan of the paint job. Additionally, minor touch-ups or spot repairs can help maintain the appearance and integrity of the paint between full repaints. Regular inspections and proactive maintenance play a crucial role in determining when it’s time for a fresh coat of paint to keep the boat looking its best and protected from the elements.

Is it worth repairing a boat?

Deciding whether to repair a boat depends on a few factors, notably the extent of damage, the boat’s value, and its sentimental or functional significance. Minor repairs, like fixing scratches or small dings, are usually worthwhile, as they help maintain the boat’s appearance and integrity. However, for major structural damage or issues that significantly impact safety or functionality, the cost and effort of repairs might outweigh the boat’s value. It’s crucial to assess repair costs against the boat’s market worth and consider how the repairs will enhance its usability and longevity. Additionally, sentimental value or the unique characteristics of a particular boat might make repairs worthwhile, even if they exceed its monetary value. Consulting with marine professionals can provide insights into the feasibility and cost-effectiveness of repairs, aiding in the decision-making process.

Hours of Operation –

MONDAY to SATURDAY – 8am to 5pm

SUNDAY – Closed

Contact Person –

Sal Duran

duransboatrepair@outlook.com

Contact –

281-799-3218

Address –

1900 Shipyard Dr. Seabrook TX 77586